Casting Machine Price

Casting Machine Price

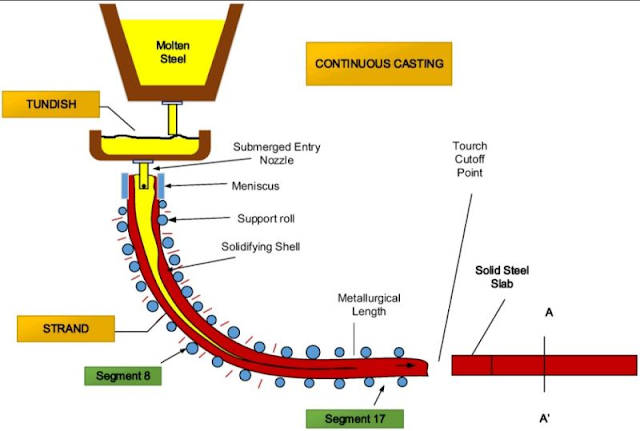

The billet caster is a fully mature technology. Among the established billet casters, the arc-shaped casters have an absolute advantage. In particular, among the newly built billet continuous casting machines in recent years, almost all of them are arc-shaped continuous casting machines except for a very small number of extra-bloom continuous casting machines.

In the arc-shaped billet continuous casting machine, the main difference lies in the type of dummy bar. At present, the flexible dummy bar and the rigid dummy bar coexist, each with its own advantages and disadvantages. The rigid dummy bar used in the small-section continuous casting machine can further simplify the structure of the support section in the secondary cooling chamber, which is convenient for accident handling in case of breakout.

Model: full arc continuous casting machine

Casting machine radius: 9/16m

Number of machines * number of streams: 4 (machines) * 4 (streams)

Flow spacing: 1200mm

Castable section: 120*120mm; 150*150mm; 180*180mm; φ140mm; φ150mm; φ155mm; φ160mm;

Fixed length: any specification (5~9 meters)

Pulling speed range: 120*120mm 3.00~3.20m/min

150*150mm 1.80~2.20m/min

180*180mm 1.30~1.60m/min

φ140mm 2.40~2.70m/min

φ150mm 2.10~2.50m/min

Billet section: 150×150mm

Vibration device: non-interference duplex full leaf spring vibration

Tensile leveling machine: fully water-cooled independent 5-roller single stand, continuous leveling.

Roller surface linear speed m/min: ~5.5

评论

发表评论