Types of Casting Machines

Types of Casting Machines

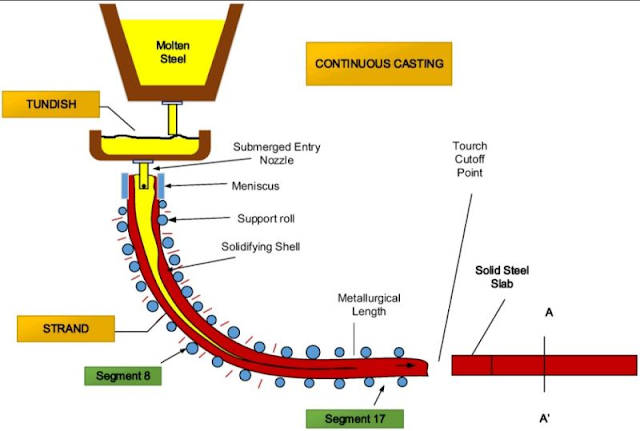

Continuous Caster machine can be classified in many forms.

At present, continuous casting machines have been widely used in steel mills, with various forms and different uses. The name of the continuous casting machine is also very inconsistent. Now we introduce the classification method of continuous casting machine according to general habits:

(1) The shape of continuous casting machine is classified as: vertical continuous casting machine, vertical bending continuous casting machine, arc continuous casting machine, low head (oval) continuous casting machine, horizontal continuous casting machine, wheel continuous casting machine, etc. .

(2) Classification according to the section of the casting billet:

- Billet continuous casting machine: The section less than or equal to 150 × 150mm is called a billet, and a section greater than 150 × 150mm is called a bloom. In the continuous casting of billet, 120×120mm is used as a dividing line. Above this value, immersion nozzle and mold slag are used for casting, and below this value, open casting or gas protection casting is used. If the ratio of the long side to the wide side of the rectangular section is less than 3, it is also called a billet continuous casting machine.

- Slab continuous casting machine: The section of the slab is rectangular. Its width to thickness ratio is generally above 3.

- Round billet continuous casting machine: the section of the billet is circular, with a diameter of Φ60~Φ400mm.

- Special-shaped billet continuous casting machine: pouring special-shaped sections such as I-beams.

- Continuous casting machine for both square and slab: on one casting machine, both slab and billet can be poured.

(3) According to the drawing speed, there are: high drawing speed continuous casting machine and low drawing speed continuous casting machine. The main difference between them is that the billet is straightened with liquid core at high drawing speed, and the billet is fully solidified and straightened at low drawing speed.

(4) Classification according to the hydrostatic head of the molten steel: the higher static pressure is called the high head type continuous casting machine, such as the vertical type and the vertical bending type continuous casting machine. The lower static pressure is called a low-head continuous casting machine such as arc, elliptical and horizontal continuous casting machines.

(5) If it is distinguished by the number of strands that the continuous casting machine can cast under a common ladle, it can be divided into single-strand, double-strand or multi-strand continuous casting machines.

.jpg)

评论

发表评论