Arc Continuous Caster

Arc Continuous Caster

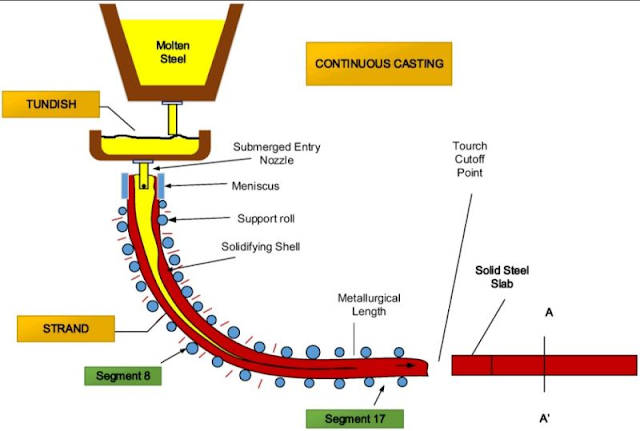

The secondary cooling device is arranged on the arc curve, the molten steel is injected vertically into the mold, the casting billet is gradually turned to the horizontal through the arc curve, and the billet is straightened and discharged from the horizontal direction.

The arc continuous caster is developed on the basis of the vertical bending continuous casting machine.

The main features of this type of continuous casting machine are:

The height of the casting machine is basically equal to the radius of the arc;

The height is lower than that of the vertical and vertical bending types;

The weight of the equipment is lighter, and the investment cost is lower;

The billet bears during the solidification process;

The hydrostatic pressure of molten steel is relatively small;

The resulting bulging phenomenon is reduced accordingly.

Since the billet is discharged from the horizontal direction, the fixed-length length of the cast billet can be unlimited.

The arc-shaped continuous casting machine can cast square billets with a minimum cross-section of 70 mm × 70 mm, as well as rectangular billets and slabs.

The earliest arc-shaped continuous caster used in industrial production was built by the Mannesmann Company of the Federal Republic of Germany in 1963.

In 1964, the slab arc continuous casting machine designed and manufactured by Comcast was put into production in Dillingen, the Federal Republic of Germany. China began experimenting with arc-shaped continuous casting in 1960.

In 1964, a large slab arc-shaped continuous casting machine was built in Chongqing No. 3 Iron and Steel Plant. The cutting adopts a 1500-ton hydraulic flying shear.

In 1967, a 1-machine 4-strand arc-shaped continuous casting machine was built in the No. 2 Steelmaking Plant of Chongqing Iron and Steel Company, which can cast 4-strand blooms at the same time. Since the advent of the arc-shaped continuous casting machine, the development of the continuous casting machine has been dominated by the arc-shaped continuous casting machine. More than 90% of the continuous casting machines built in the world belong to arc-shaped continuous casting machines.

According to the structure of the mold and the shape of the arc curve, the arc continuous casting machine is divided into full arc, straight arc and ellipse.

Full Arc Continuous Caster

It is a single-point straightening arc continuous casting machine. The characteristic is that the mold and the secondary cooling device are arranged on the arc of the same radius. The blank is produced in the direction, and then cut to a fixed length by a cutting car. The full arc continuous casting machine includes tundish, mold, vibration mechanism, secondary cooling section, tension leveler, cutting car, billet roller table and other parts.

Straight Arc Continuous Caster

It is an arc-shaped continuous casting machine with a straight line segment, and it is an arc-shaped continuous casting machine with multi-point bending and multi-point straightening. The process feature is that molten steel is injected into a vertically placed straight mold, and there is a 2 to 3-meter vertical slab guide section under the mold. The second cooling zone gradually solidifies but still has a liquid core, and the billet is straightened at multiple points in a continuous manner, and the billet is discharged horizontally and cut to length.

The advantages of the straight arc continuous casting machine are:

① The slab solidifies in a long vertical section composed of a vertical mold and a secondary cooling straight section, which creates favorable conditions for the floating of large inclusions in the molten steel and reduces the arc continuous casting. The inclusions at 1/4 of the inner arc side are easily generated in the casting billet of the casting machine, which is beneficial to improve the cleanliness of the casting billet.

②The billet is bent into an arc shape with a liquid core, so that the equipment height of this model is only slightly higher than that of the full arc continuous casting machine, and far lower than the vertical bending continuous casting machine.

③Because of the continuous multi-point bending and straightening, it can ensure that the slab will not crack in the two-phase region.

Compared with the full arc continuous casting machine, the shortcomings of the straight arc continuous casting machine are:

① Due to the addition of a bending section, the equipment is relatively complex, and the workload and difficulty of adjustment and maintenance are slightly increased.

②The height of the casting machine is higher than that of the arc machine, so that the bulging deformation of the casting billet caused by static pressure increases, and the bending deformation of the two-phase region increases the possibility of internal cracking of the casting billet.

③Because the height of the casting machine is slightly higher and the equipment is more complicated, the capital construction investment and equipment cost also increase accordingly.

Since the internal quality of the slab produced by the straight arc continuous casting machine is better than that of the full arc continuous casting machine, it is conducive to the production of high-quality products, especially thin plate varieties and steel grades with good deep drawing properties, so after the 1990s , The straight arc continuous casting machine has been paid attention to, especially in Japan, the slab casters built are basically straight arc.

Oval Continuous Caster

Also known as super low head continuous casting machine, it is a multi-point straightening arc continuous casting machine.

The characteristic is that the curvature radius of the arc part is changed in sections, so that the mold and the second cooling section pinch rollers are arranged on a quarter elliptical arc. Models with this structure use multiple radii except for the arc-shaped area, and their basic characteristics are the same as those of the arc-shaped continuous casting machine. Due to the small starting radius (the arc radius of the mold and the radius of the upper section of the secondary cooling zone), the overall height of the continuous casting machine is low, which is suitable for construction in low-height workshops. But because it has multiple radii, the installation and adjustment of the casting machine are more complicated, and the maintenance is also more difficult.

The combination of ultra-low head continuous caster and pure molten steel production technology can produce defect-free slabs that meet the quality requirements of hot feeding and direct rolling, such as thin plates, deep-drawing plates, tin-plated plates, thick plates, and straight seam submerged arc welding. (UOE) steel pipe and spiral welded steel pipe plate, shipbuilding plate, stainless steel plate and other slabs, the construction investment is 20% to 30% lower than the full arc continuous casting machine.

评论

发表评论