Vertical Continuous Caster

Vertical Continuous Caster

Both the casting and slab solidification processes are continuous caster that are carried out in a vertical state. It is the earliest continuous casting machine used in industrial production.

In 1933, German S. Junghans invented the crystallizer vibration technology, which solved the problem of leakage caused by the adhesion of the initial solidification shell and the mold, and the continuous casting machine entered industrial application.

The world's first industrial pilot vertical caster was built in 1946 at the Laumore plant in the UK for casting small section billets.

The first vertical billet caster for industrial production was built in 1952 at the Barrow Steel Works in the UK.

The first slab continuous casting machine (semi-continuous vertical casting machine, slab cross-section 180 mm × 800 mm) was built in the Soviet Red October Steel Works.

China's first industrial test vertical continuous caster was built in 1956 at the Shanghai Iron and Steel Research Institute.

The first industrial production vertical continuous caster was built in 1958 at the No. 3 Iron and Steel Plant in Chongqing, China, with a casting section of 170 mm x 250 mm.

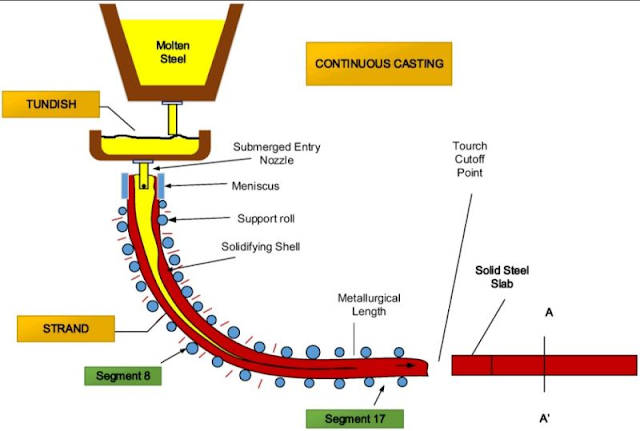

A series of equipment and operations such as the tundish, mold, secondary cooling support and guide device, tension leveler, slab cutting equipment, etc. of the vertical continuous casting machine are arranged on a vertical centerline. After the molten steel is injected into the mold from the tundish, the initial solidified billet is accelerated and solidified by the secondary cooling zone, and is pulled out by the set drawing speed of the billet drawing machine. After cutting, the fixed-length billet enters the turning bucket.

After the tipping bucket receives the slab, the slab is placed in a horizontal state and transported out by the conveying roller table (the pit caster has a hoist, which lifts the slab to the ground level and then outputs it from the ground roller table), or is transported by the tipping bucket. Inclined to the inclined crawler conveyor, the crawler conveyor will send the billet to the ground and output by the ground roller table, and then the billet will be pushed to the centralized cooling bed by the steel pulling (or steel pushing) machine.

The main process characteristics of vertical continuous casting are:

①The molten steel is injected into the upright mold from the tundish. Large inclusions and some small inclusions in the molten steel may float to the surface. When casting with mold slag, the inclusions can be absorbed by the mold slag, and the inclusions remaining in the slab The distribution of impurities is relatively uniform, and there will be no accumulation of inclusions in the billet on the inner arc surface during arc continuous casting.

②The casting billet is cooled evenly and the solidification structure is symmetrical.

③The casting billet is not affected by external forces such as bending and straightening during the solidification process and in the casting machine, and there will be no crack defects caused by mechanical stress inside the billet. Vertical continuous casting is suitable for casting alloy steel and steel with high crack sensitivity.

The total height of vertical continuous casting equipment is large. Since the slab solidifies in a vertical state, the total height of the equipment will also increase with the increase of the section of the casting slab and the increase of the drawing speed. The longer the fixed length of the slab, the greater the height of the continuous casting machine.

Generally, the height of the vertical casting machine is twice as high as that of the arc-shaped continuous casting machine. For casting billets of the same section, the arc-shaped casting machine is only 1/3 of the height of the vertical casting machine. For example, the height of the large slab or billet continuous casting machine (the vertical distance from the casting platform to the upper surface of the output roller table) is more than 30 meters, and the height of the vertical continuous casting machine for casting smaller sections also needs to be about 20 meters.

Vertical continuous casting machine can be divided into two types: overhead type and pit type. The overhead type is that the continuous casting machine is built on the ground, and the pit type is built under the ground, but the general vertical continuous casting machine is half built on the ground and half built underground, which is called semi-elevated type or semi-pit type. .

The capital construction of vertical continuous caster is large, and the construction cost of workshop or pit is high. In addition, it is more troublesome to transport the slab, and once the casting process fails, the casting machine can only stop working. Since the advent of the arc continuous casting machine in the 1960s, the vertical continuous casting machine has basically been replaced by the arc continuous casting machine.

评论

发表评论