Characteristics of Three-electric Control System of Continuous Casting Machine

Characteristics of Three-electric Control System of Continuous Casting Machine

1. Basic Automation System

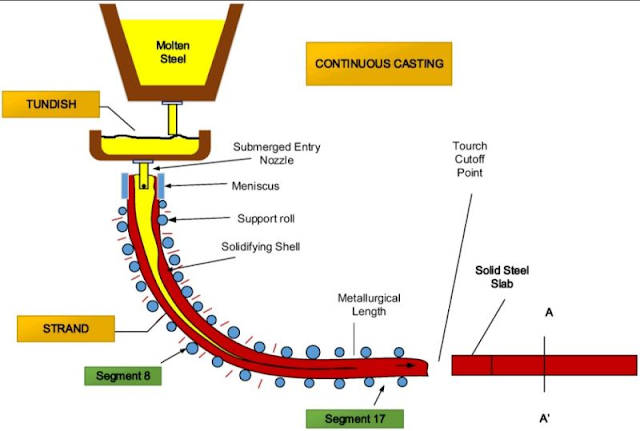

The components of the continuous casting electrical control system are mainly composed of electrical, instrumentation, operation control station, and PLC. Through the interaction and coordination of these types of equipment, not only the field data collection and process control are realized to a large extent It has a significant effect on perfecting the order of using the equipment, improving the specific effect of operation monitoring, and finally forming a good quality control of the slab.

2. Continuous Casting Machine Electrical Drive and Instrument System

The square billet arc continuous casting machine forms a manual switching mode through the two-way wire feeding method and divides the motor transmission mechanism into ordinary AC and AC frequency conversion control methods. The instruments used in the process mainly include electromagnetic flowmeters and transmitters. Device and temperature measuring instrument. As the core component of molten steel temperature measurement, the use of consumable thermocouples and secondary instruments not only improves the monitoring effect but also facilitates the formation of secondary data and provides help for subsequent data analysis.

3. Power Purification Device and Anti-interference System

The power purification device is the prerequisite for the stable operation of the continuous casting machine. Because the most important core element of a continuous casting machine is continuity, and to improve the continuity of a square billet arc continuous casting machine, it must be reflected and maintained by the stability of electrical equipment. In practical applications, casting and industrial PLC system cities are transformed by isolation transformers, and electrical integration is achieved by changing 380V to 220V, which promotes the level of automation of the three electrical integration. The grounding device reduces the interference of electrical equipment and improves the operating efficiency of the PLC.

4. Operation station failure countermeasures and PLC processing countermeasures

In general, in order to respond to sudden failures, the main operating room needs to prepare two operating stations at the same time, so that when a problem occurs and a fault can be quickly switched to perform standby monitoring, thereby improving the operation of the PLC processor Stability also provides necessary equipment guarantee and system guarantee for the safe operation of the entire process.

In summary, as a more advanced continuous casting equipment, the round billet arc continuous casting machine can achieve the purpose of improving the quality of the billet and promoting production efficiency through the automatic control of the system. Because this metallurgical equipment has a switchable effect, it increases the overall economic benefits of the enterprise, and at the same time avoids the problem of heavy maintenance and heavy burden caused by repeated purchases of metallurgical equipment. I hope that this article can contribute to the modernization and sustainable development of China's steel-related industries.

评论

发表评论