Continuous Casting Machines Classification

Continuous Casting Machines Classification

Continuous Casting Machines are Classified According to Their Use and Function.

Continuous casting machines are classified according to their use and function:

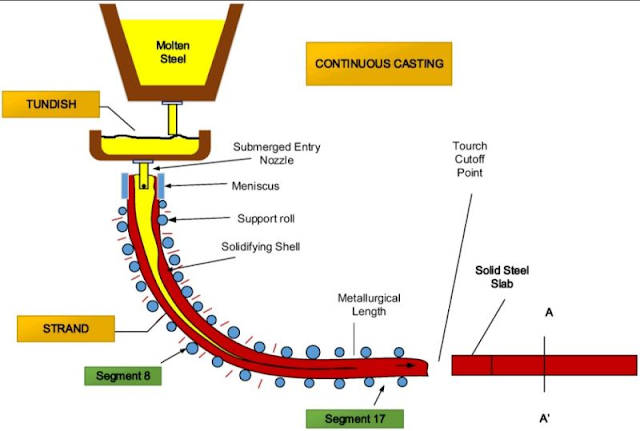

Continuous casting machines can be classified in many forms. According to the structural shape, the continuous casting machine can be divided into vertical continuous casting machines, vertical bending continuous casting machines, straight-line curved continuous casting machines, curved continuous casting machine, multi-radius elliptical continuous casting machine, and horizontal continuous casting. machine. In recent years, with the development of continuous casting technology, the development of wheel continuous casting machines, especially thin slab continuous casting machines, has been carried out.

If the size and shape of the section cast by the continuous casting machine are distinguished, the continuous casting machine can be divided into a slab continuous casting machine, a billet continuous casting machine, a bloom continuous casting machine, a round billet continuous casting machine, and a profiled section. Continuous casting machine and thin slab continuous casting machine. In the billet continuous casting machine, a rectangular billet continuous casting machine is also included. Generally, a cast billet having a casting section or an equivalent sectional area of more than 200×200 mm is called a bloom, and a billet having a section or equivalent sectional area of less than 160×160 mm is called a billet. A rectangular blank having a width to thickness ratio greater than 3 is called a slab.

If the continuous casting machine is divided by the number of casting streams that can be cast under a single ladle, it can be divided into single-flow, double-flow or multi-flow continuous casting machines.

评论

发表评论