Vertical Continuous Casting Machine and Vertical Bending Continuous Casting Machine

\

Vertical Continuous Casting Machine and Vertical Bending Continuous Casting Machine

Vertical Continuous Casting Machine

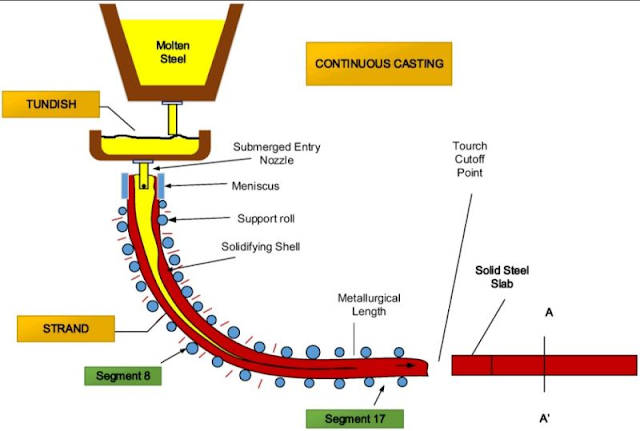

The vertical continuous casting machine is the main model before the 1950s and 1960s, and its structure is shown in the figure below. The molten steel watering system, the crystallizer, the cutting device and the steel billet exit position of the continuous casting machine are arranged on the vertical axis of the continuous casting machine.The entire equipment takes up a lot of space in the workshop. When the vertical continuous casting machine is produced, the slab is solidified in the crystallizer and the second cooling section. Because of the vertical arrangement, the non-metallic inclusions in the liquid metal are easy to float, the heat dissipation around the slab is relatively uniform, and the slab is drawn. The process is not subject to other bending forces, and the resulting slab is of good quality and is not susceptible to cracking, so it is more suitable for the production of alloy steel and other steels sensitive to cracks. However, the height of the continuous casting machine is too large, the investment in infrastructure and equipment is large, and the maintenance is difficult. Because of the high head casting, the lower part of the slab is prone to deformation of the drum under the hydrostatic pressure of the molten steel, so it is only suitable for small production section slab.

Vertical Bending Continuous Casting Machine/Vertical Bending Caster

The vertical curved continuous casting machine is a transitional type developed on the basis of the vertical continuous casting machine. Its upper part is the same as the vertical continuous casting machine. The difference is that the vertical bending type continuous casting machine uses the top bending device to bend the casting blank 90° after it is completely solidified so that the casting blank is tapped and cut in the horizontal direction. The vertical bending type continuous casting machine partially reduces the height of the whole machine, but since the slab is completely solidified and then bent, it is prone to cracks and the like during production and is mainly used for the production of small-section blanks.

评论

发表评论