Improvement Measures for Continuous Casting Machine in Smelting and Continuous Casting

Improvement Measures for Continuous Casting Machine in Smelting and Continuous Casting

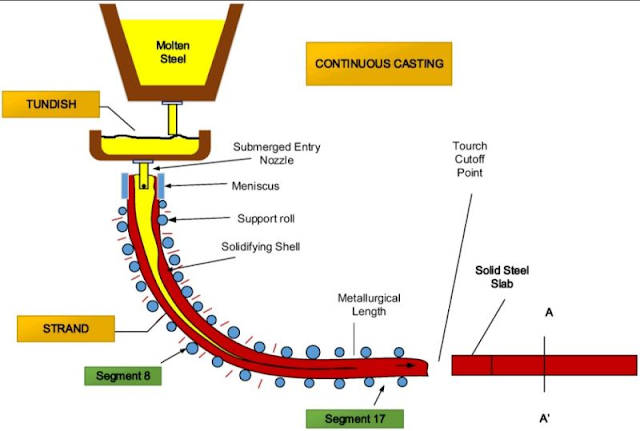

According to the different rolling process, the continuous casting machine is famous for its high efficiency and low energy consumption. During the operation, the scrap steel is transferred through the ladle after smelting, and the temperature of the molten steel is determined according to the lifting distance and the temperature in the workshop to avoid the temperature drop of the molten steel being too fast, resulting in the phenomenon of stacking and blocking when pouring into the continuous casting machine, resulting in molten steel. The slow flow rate seriously affects production capacity.

Since the outside temperature is low, the temperature of the molten steel drops rapidly, and the temperature is continuously lowered by the temperature. In order to solve this problem, an insulated steel ladle can be used to maintain the temperature of the molten steel to ensure that the molten steel does not become viscous in the continuous casting machine. Continuous casting machine continuous casting slab is difficult and can be warmed by external oxygen blowing. Therefore, the continuous casting machine must meet the requirements of “first continuous casting and post-blowing oxygen”. At the same time, the slab is sprayed and cooled with cooling water and cut into the roughing mill.

These are some improvements in the synergy of continuous casting machines in terms of smelting and continuous casting. As long as they are operated in the above manner, the practical application effect of the continuous casting machine will be greatly improved. Of course, the configuration of the continuous casting machine itself, especially its roller section, cannot be ignored.

The design and manufacture of the roller section of the continuous casting machine is specific to the specifications of the equipment and the type of rolling. The requirements for high degree of mechanization are different. For example, large rolling mills must be equipped with turning steel rollers, automatic lifting rollers and fully automatic. Step type cooling bed. Continuous casting machines generally include two major parts, the main equipment, and the auxiliary machinery. The proportion of equipment software and kits is also large.

The technological progress of the continuous casting machine is mainly focused on the shortening and simplification of the production process, and finally the formation of high-quality material properties of the continuous casting machine, diversification of equipment specifications and computerization of control and management. The passages on the roller table form a reliable lubrication and heat dissipation system, coupled with a good sealing device, allowing the continuous casting machine bearings to operate stably in high-speed and high-pressure conditions.

评论

发表评论