Hydraulic Oscillation Control System for Horizontal Continuous Casting Machine

Hydraulic Oscillation Control System for Horizontal Continuous Casting Machine

The hydraulic oscillation control system in the horizontal continuous casting machine has passed 6 million oscillation tests in succession, and the test data results completely meet the actual production requirements, and the equipment is intact. Because the hydraulic cylinder is designed with a sealed structure, not only does it not leak, but the life of the seal is also greatly improved, making the operating cost of the system much lower than that of the mechanical oscillation system.

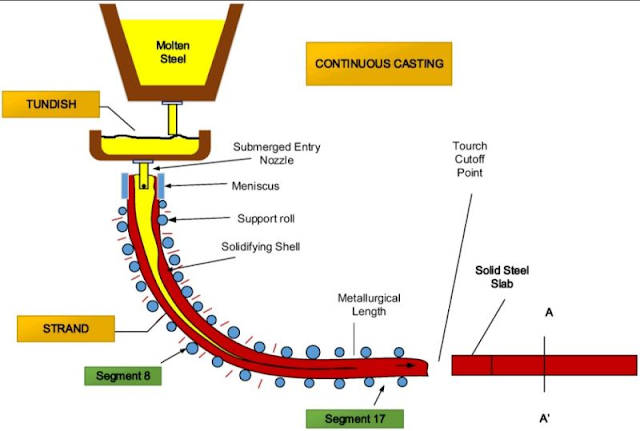

The conflicting force of the mold wall against the moving shell is considered to be an essential element in tearing the shell and constraining the casting speed. There is a liquid slag film between the green shell and the crystallizer wall. The conflict here is a vicious conflict, that is, the collision force is proportional to the relative motion speed, and the slag film viscosity is inversely proportional to the slag film thickness.

In this way, the conflicting force and the tensile stress on the shell during the slippage of the crystallizer oscillation are large, and the shell of the green shell may be cracked. For this purpose, a non-sinusoidal oscillation skill is developed to reduce this conflicting force. Theoretical studies and simulation experiments indicate that proper selection of non-sinusoidal oscillation parameters can reduce the collision force by 50% to 60%.

The horizontal continuous casting machine has been briefly modified to complete 400 hydraulic oscillations, the partial slope reaches 50%, and can be adjusted online, which is a new skill for the completion of the high-quality, high-yield horizontal continuous casting machine. When the bus voltage is detected to rise instantaneously, the inverter will increase the output frequency appropriately to reduce the regenerative energy that causes the bus voltage to rise. This reduces the possibility of overvoltage faults in the inverter.

In the process of using a horizontal continuous casting machine, the occurrence of faults is a kind of damage to the operation process and the quality of equipment and personnel safety. When the flow rate of cooling water around the outer wall is uneven, it is easy to attack. Refined copper water jacket skills. The refined copper water jacket skill, the uniformity of the gap between the water jacket and the crystallizer is very important.

In order to deal well with the shape of the inner cavity of the water jacket and the standard precision control problem, many copper pipes used by steel mills are now produced by kneading molding skills. The inner diameter, shape and standard handling of the copper pipe have reached high precision. If the copper pipe production skill can be used to produce the water jacket, this problem is solved.

评论

发表评论